SERVICES

Experts in Production Run, Light-Gauge, Custom Sheet Metal Fabrication and Design

At Mika Metal Fabricating, we deliver more than just parts — we provide complete custom sheet metal fabrication solutions built around precision, consistency, and quality. Our sheet metal fabrication capabilities in Willoughby, Ohioset us apart as a leading provider in the region. With advanced machinery and a highly skilled team, we support everything from early prototypes to full production runs with exceptional accuracy and efficiency.

Proudly serving Cleveland, Northeast Ohio, and customers across North America, we take pride in delivering precision metal fabrication services that meet tight tolerances, demanding standards, and your exact specifications. No matter the scope or complexity, we ensure your project is built right — every time.

Mika is pleased to offer these services:

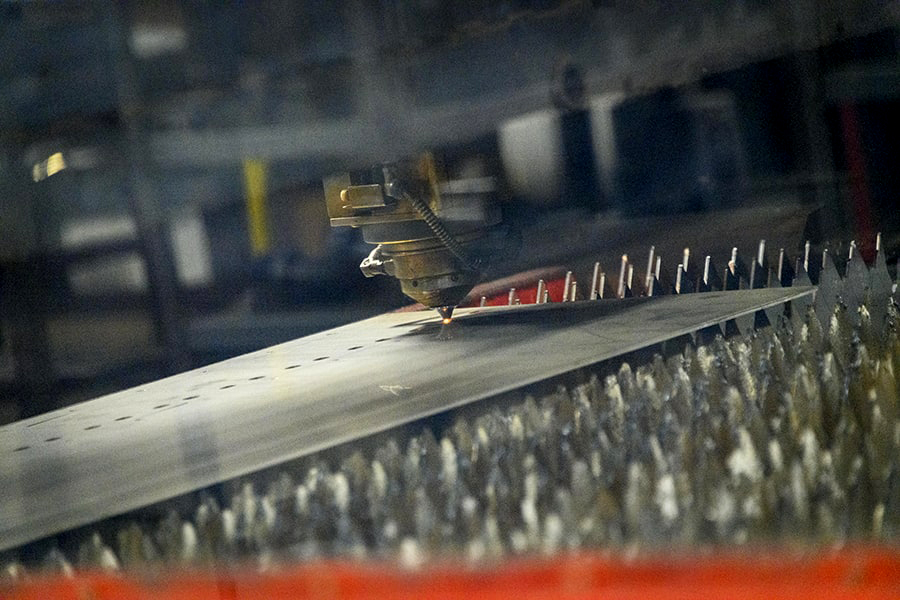

Laser Cutting and Etching

Our advanced laser cutting systems deliver clean edges, tight tolerances, and highly detailed designs with exceptional speed and accuracy. This process is ideal for enclosures, brackets, panels, and custom components. Laser cutting also helps reduce material waste while improving repeatability, giving you consistent results on every production run.

CNC Punching

For larger production runs — or for parts that require multiple hole patterns, louvers, or embosses — CNC punching offers both efficiency and precision. Our turret punches can accommodate a wide range of sheet sizes and thicknesses, which gives us the flexibility to support diverse part geometries and industries.

Forming

Precision forming ensures every component matches your exact design specifications. With state-of-the-art press brakes, we produce consistent bends, angles, and geometries for both small and large production runs. Our forming expertise delivers accuracy you can rely on and repeatability that keeps every part within tolerance.

Finishing

Our finishing capabilities create uniform, production-ready surfaces on steel, stainless, perforated metals, and aluminum. We use controlled deburring, edge rounding, and surface conditioning to remove burrs and smooth profiles. These processes also establish consistent grain patterns that meet strict surface-quality requirements. As a result, each part transitions cleanly into powder coating, screen printing, assembly, or final delivery.

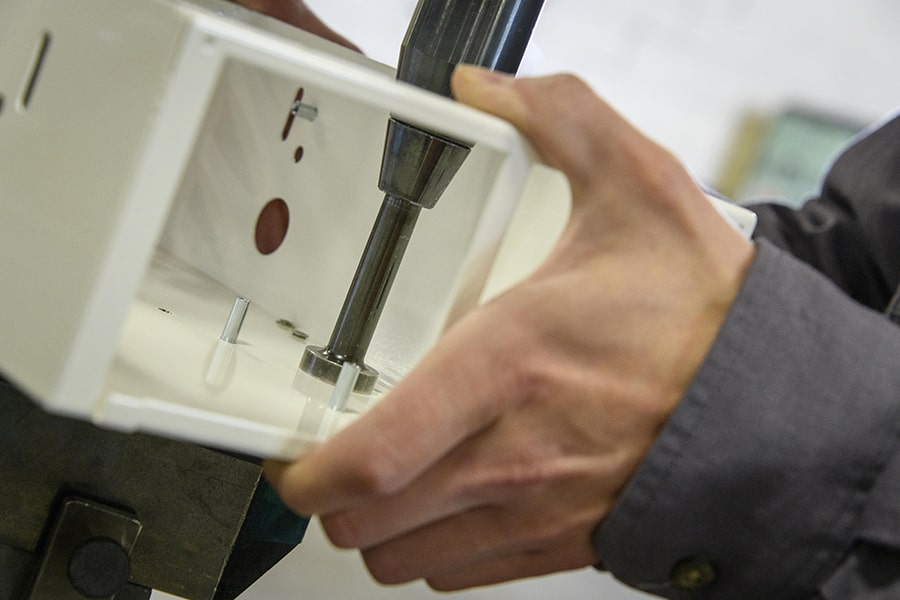

Drilling & Tapping

Our drilling and tapping capabilities deliver precise holes, threads, and mounting points with clean edges and tight tolerances across steel, stainless, perforated metals, and aluminum. This level of accuracy helps reduce lead times, improves downstream fit and function, and ensures every part integrates seamlessly into your final assembly.

Spot Welding

Our spot welding capabilities produce high-strength fusion points through controlled heat input and consistent electrode pressure, ensuring repeatable weld penetration across steel, stainless, perforated metals, and aluminum. As a result, each weld achieves durable joints with reduced distortion and dependable structural integrity, supporting reliable performance across all parts and assemblies throughout production.

MIG/TIG Welding

Mika Metal delivers MIG, TIG, and spot welding for steel, stainless steel, and aluminum. Each material receives the correct process for strength and precision. Our welders focus on both performance and appearance. They produce clean, reliable, and consistent welds. Our capabilities also support industries such as medical devices, electronics, and industrial machinery, where compliance and consistency are critical.

Hardware Insertion

Our hardware insertion capabilities ensure precise and secure installation of PEMs, standoffs, nuts, studs, and other fasteners. We apply controlled force, accurate alignment, and repeatable depth across steel, stainless, perforated metals, and aluminum. This results in strong mechanical joints, reduced assembly time, and reliable part performance in every production run.

Assembly

Our assembly capabilities support everything from simple welded components to complex builds. We handle precise alignment and the integration of multiple subassemblies. Our team combines fasteners, studs, nuts, and other hardware to create fully finished, production-ready parts. This process helps streamline your workflow and reduces overall manufacturing time.

Powder Coating

We offer in-house powder coating to meet your branding and product requirements. This durable finish resists wear, improves appearance, and extends the life of fabricated components.

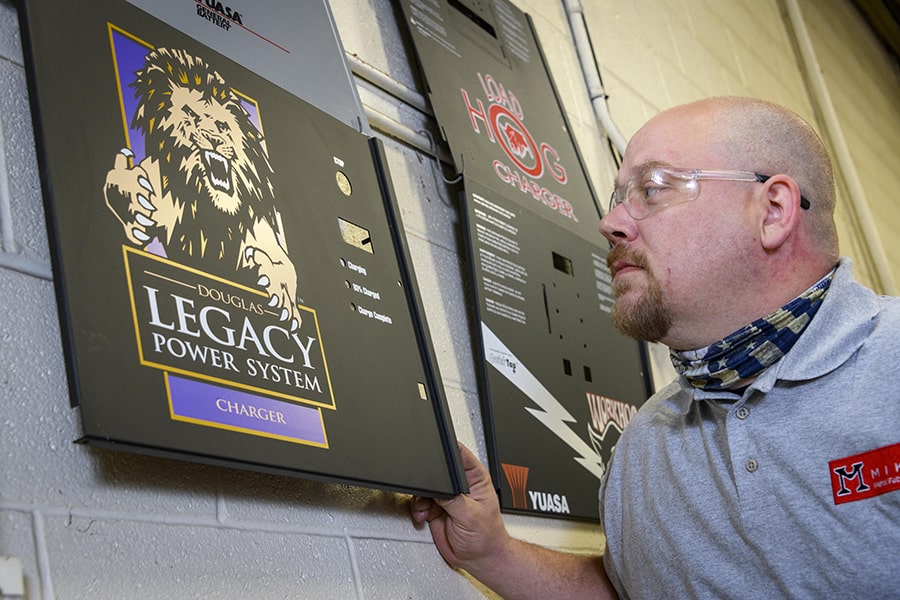

Screen Printing and Pantone Matching

For branding, instructions, or compliance information, our silk screening services provide precise Pantone color matching and a durable, high-quality finish that integrates directly into your product design.

Quality Assurance and Service Standards

Every part that leaves Mika Metals undergoes a thorough inspection process — from first-piece approvals to in-process checks and final audits. Our white glove handling, careful packaging, and just-in-time delivery ensure that your parts arrive exactly when you need them, in perfect condition.

EQUIPMENT

Part and Assembly Size Requirements

- Minimum: 1” x ½”

- Maximum: 5’ x 10’

Quantities

Optimal quantities can vary from as little as 10 pieces up to thousands of pieces depending on size, complexity and number of assemblies involved in your project.

Prototyping

Mika is pleased to offer product and part prototyping. Should your concept make it to a full production run, we’ll credit back a mutually agreed upon portion of the cost against your order.